Using Maths channel to Tune for Volumetric efficiency

Posted: Tue Dec 13, 2016 12:04 am

Am still at the start of my Syvecs tuning journey, working out how to get to grips with how to best tune my engine.

Due to the potentially unusual temperatures created in and around the engine bay, I am not a huge fan of Dyno tuning although have to agree the Dyno is a safer method, so wanted to use the datalogging and Maths channel potential of the Syvecs system to capture whether the correct steps were being taken to set the engine up correctly.

I can see scenarios where it would be possible to poorly set the cam timing, or set too high a boost yet optimise the fuel and ignition to give a false impression that the maximum power had been extracted from the engine. Similarly ambient air pressure needs to be accounted for.

My hope is that optimising the engines Volumetric efficiency to maximise the mass of oxygen the engine is pumping is an important step on the path to maximising power.

Given that the volume of air is significantly affected by temperature, it is important to remove the effect of the ambient air temperature from the calculations since intercooler efficiency improves greatly on a cold day.

There may be additional factors on air temperature that are not captured with the following routine, but I have chosen to calculate Volumetric Efficiency using the theoretical mass of air consumed by a 100% efficient non-aspirated engine compared to the actual throughput of the engine to account for ambient pressure and temperature.

Tuning for maximum Volumetrical efficiency will hopefully allow the maximum possible power output once AFR and Ignition timing have been optimised.

Step 1 was to use the Maths channels in SView to calculate the airflow mass in lbs of air through the turbo engine. There is a thread here that describes the steps to create a Maths channel and also calculate the mass of air the engine is consuming viewtopic.php?f=4&t=843

The VE formula being used is:- Mass of air being consumed / calculated mass that a 100% efficient non-turbo engine would consume.

The one parameter that I do not appear to have access to in the Syvecs ECU is the ambient air temperature. This information is available on the R35 GTR dashboard, perhaps someone can advise if there is a way to bring this parameter into the Syvecs logs through the CAN system?

Calculating the maximum theoretical air mass of the non-aspirated engine is a function of engine capacity x RPM x barometric air pressure x correction for ambient air temperature.

Density for a given temperature can be expressed as:- Pressure / Gas constant * temperature °K

Where pressure is Pascals (millibar * 100)

Gas constant, J/(kg*degK) = 287.05 for dry air

T = temperature °K = deg C + 273.15

The density of 15°C air at sea level is therefore = 101325 / (287.05 * (15 + 273.15)) = 1.2250 kg/m3

Air density in a Syvecs Maths channel will in my case need ambient temperature 15°C added in manually, so will look like this:- bap*100/(287.05*(15 + 273.15))

The 100% VE normally aspirated calculation for the mass of dry air in lbs per minute will therefore be RPM*(engine capacity in litres/2/1000)*density*conversion from kg to lb, as follows:- rpm*3.8/2/1000*bap*100/(287.05*(15 + 273.15))*2.20462

Calculating the actual VE of the engine is now straightforward using the earlier Air flow per turbo calculation.

Need to remove the 2 that was at the end of the formula since we now need engine airflow rather than turbo airflow. 14.7*lam2*sqrt(12.47267*relFp1/2999)*fuelDutyPri1/100*6

Combining into a % VE, it looks like this. (14.7*lam2*sqrt(12.47267*relFp1/2999)*fuelDutyPri1/100*6)/( rpm*3.8/2/1000*bap*100/(287.05*(15 + 273.15))*2.20462)*100

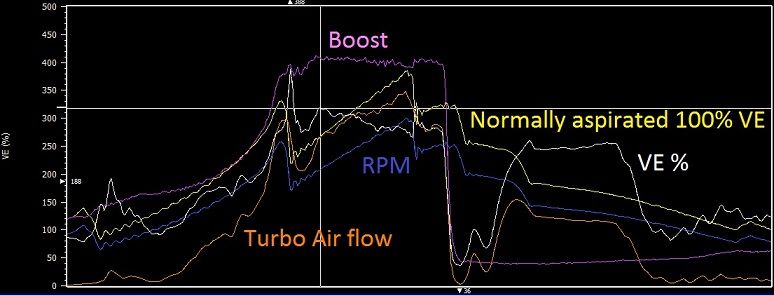

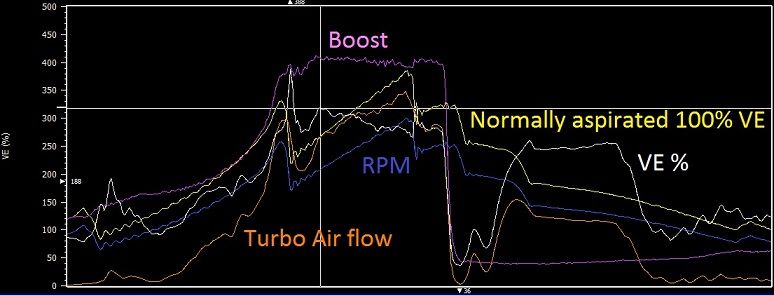

Not done any work with it yet, but here is what the VE log looks like on a short pull, it shows that the engine VE peaked at theoretical 320% mass at 4200RPM.

Going to play around with the cam timing first to see what I can find out.

Hopefully the logic stacks up, let me know if I got it wrong / needs adjusting.

Due to the potentially unusual temperatures created in and around the engine bay, I am not a huge fan of Dyno tuning although have to agree the Dyno is a safer method, so wanted to use the datalogging and Maths channel potential of the Syvecs system to capture whether the correct steps were being taken to set the engine up correctly.

I can see scenarios where it would be possible to poorly set the cam timing, or set too high a boost yet optimise the fuel and ignition to give a false impression that the maximum power had been extracted from the engine. Similarly ambient air pressure needs to be accounted for.

My hope is that optimising the engines Volumetric efficiency to maximise the mass of oxygen the engine is pumping is an important step on the path to maximising power.

Given that the volume of air is significantly affected by temperature, it is important to remove the effect of the ambient air temperature from the calculations since intercooler efficiency improves greatly on a cold day.

There may be additional factors on air temperature that are not captured with the following routine, but I have chosen to calculate Volumetric Efficiency using the theoretical mass of air consumed by a 100% efficient non-aspirated engine compared to the actual throughput of the engine to account for ambient pressure and temperature.

Tuning for maximum Volumetrical efficiency will hopefully allow the maximum possible power output once AFR and Ignition timing have been optimised.

Step 1 was to use the Maths channels in SView to calculate the airflow mass in lbs of air through the turbo engine. There is a thread here that describes the steps to create a Maths channel and also calculate the mass of air the engine is consuming viewtopic.php?f=4&t=843

The VE formula being used is:- Mass of air being consumed / calculated mass that a 100% efficient non-turbo engine would consume.

The one parameter that I do not appear to have access to in the Syvecs ECU is the ambient air temperature. This information is available on the R35 GTR dashboard, perhaps someone can advise if there is a way to bring this parameter into the Syvecs logs through the CAN system?

Calculating the maximum theoretical air mass of the non-aspirated engine is a function of engine capacity x RPM x barometric air pressure x correction for ambient air temperature.

Density for a given temperature can be expressed as:- Pressure / Gas constant * temperature °K

Where pressure is Pascals (millibar * 100)

Gas constant, J/(kg*degK) = 287.05 for dry air

T = temperature °K = deg C + 273.15

The density of 15°C air at sea level is therefore = 101325 / (287.05 * (15 + 273.15)) = 1.2250 kg/m3

Air density in a Syvecs Maths channel will in my case need ambient temperature 15°C added in manually, so will look like this:- bap*100/(287.05*(15 + 273.15))

The 100% VE normally aspirated calculation for the mass of dry air in lbs per minute will therefore be RPM*(engine capacity in litres/2/1000)*density*conversion from kg to lb, as follows:- rpm*3.8/2/1000*bap*100/(287.05*(15 + 273.15))*2.20462

Calculating the actual VE of the engine is now straightforward using the earlier Air flow per turbo calculation.

Need to remove the 2 that was at the end of the formula since we now need engine airflow rather than turbo airflow. 14.7*lam2*sqrt(12.47267*relFp1/2999)*fuelDutyPri1/100*6

Combining into a % VE, it looks like this. (14.7*lam2*sqrt(12.47267*relFp1/2999)*fuelDutyPri1/100*6)/( rpm*3.8/2/1000*bap*100/(287.05*(15 + 273.15))*2.20462)*100

Not done any work with it yet, but here is what the VE log looks like on a short pull, it shows that the engine VE peaked at theoretical 320% mass at 4200RPM.

Going to play around with the cam timing first to see what I can find out.

Hopefully the logic stacks up, let me know if I got it wrong / needs adjusting.